Researchers examine best way to weld next class of steels for auto industry

As cars have gotten sleeker and lighter over the decades, nostalgia about cars of yesteryear often romanticize their sturdiness – huge boxes of steel ready to take on any impact. It is a memory often not rooted in the reality of the safety of today’s vehicles.

“People have dismissed the idea of lighter cars for decades because you feel safer in a big, heavy car, but that’s not always the case. If I can make something out of a stronger steel, I can use less steel,” said Dr. Luke Brewer, an engineering researcher at The University of Alabama. “It’s all about saving weight while maintaining crash worthiness.”

Since humans began smelting iron and carbon in antiquity, steel has continuously become stronger. A new class of steel, known as advanced, or ultra, high-strength steels, is emerging in auto manufacturing.

The stronger the steel, the less is needed. The less steel, the less weight. The less weight, the less the engine has to work to move the car. The less the engine works, the less fuel needed. And, voila, an improvement in fuel economy, something governments require to lessen emissions and consumers desire to cut operating costs.

But transitioning to a new steel is not as simple as swapping out the metal at the factory. Ultra-high strength steels are different in their makeup from other steels, and so what works with the steel of today might not work with the steel of tomorrow.

In making a car, steel needs to connect somehow through mechanical methods, such as fastening or interlocking, or through melting the metal together, a process called welding. A widely used joining method in modern cars is a type of welding known as resistance spot welding, but joining ultra-high strength steels this way creates challenges.

Changing welding methods at a factory would be a costly move, so the question becomes, can the steel be welded together using a carmaker’s existing technology?

“These companies are always trying to get higher performance and to do something new,” Brewer said. “They want to use the new steel for weight savings, but they will not do so until any welding challenges have been solved.”

One of the companies working to understand and meet this challenge is Daimler, the German auto giant with a manufacturing plant a short drive away from the University, Mercedes Benz U.S. International. Researchers in Germany and engineers in Alabama are collaborating with Brewer and others at the University to understand the welding of this new steel and if it can be integrated into its production lines.

“You’re trying to get into something that will get you higher performance, but you have to work around the welding challenges that higher-performance designs can create,” Brewer said. “Mercedes would like to do something even better, but one of the things getting in the way is the ability to weld this steel optimally.”

Liquid Metal

Mercedes’ factory in Alabama uses robotic resistance spot welding to join the body in white, the unpainted car before adding mechanical or electrical parts. Resistance spot welding uses a directed electric current to generate heat and force that presses a metal together in –aptly – one spot, rather than using a welding torch to melt metal together along a seam, as welding is often depicted on television and movies.

Spot welding is fast, powerful and clean. The robotic resistance spot welding machines used by Mercedes in Alabama inject roughly 7,000 amps of current through the steel in less than a second, leaving a circle no bigger than a dime in its wake. Each spot can hold up to 4,000 pounds, depending on use, and a vehicle has thousands of welds, as if the car was nailed together by electricity.

To protect against corrosion, steels are often coated with zinc, however during welding, cracks can form in the heated areas when the zinc coating melts and reacts with the underlying steel, a condition called liquid metal embrittlement.

With ultra-high strength steels, welding could exaggerate the embrittlement into a potential structural condition. If Mercedes is going to use resistance spot welding with ultra-high strength steels, its researchers and engineers must understand the phenomena.

“Universities are good at answering why,” Brewer said. “You could solve the problem in industry, but you may not have the opportunity to understand the fundamental reasons why it went away. If you want to be able to do it more efficiently in the future, you need to understand why.”

Understanding the Fundamentals

To help with that understanding, Mercedes donated to UA the same resistance spot welding system as used at its Alabama factory. “The point of using the same system is for the research project to be really well integrated into what happens on the factory floor,” Brewer said.

With the same materials and same robot, UA researchers examine the welds using two approaches – at the microscopic level and with computer simulations.

“We’re trying to better understand the fundamentals of what’s going on when you weld the steel, and then we hope to come up with conditions that improve welding and prevent embrittlement,” Brewer said.

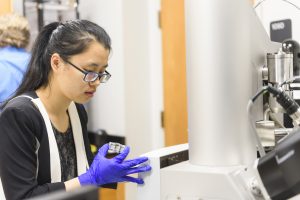

Welding samples are taken to the UA Central Analytical Facility, which houses high-powered microscopes and probes used to see the weld at the micron level. There, doctoral student Tian Liu can see the structure of the steel, which helps the team grasp how the steel and zinc behave during and after the weld.

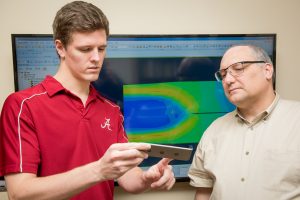

Also, Dr. Mark Barkey at UA and his students are building computer simulations of the welding process, using the welding system to validate the computer model.

“We can save a lot of physical time by doing it on a computer because we can explore and investigate a lot more welding parameters,” Barkey said. “We can tell them the best or worse cases for a weld and use that information in the lab.”

“After all, there is not a question of ‘Can these zinc-coated steels be welded?’ but instead ‘How can they be welded to create a strong, car body?’” Barkey said.

Two undergraduate students and a master’s degree student work with Brewer and Barkey, giving them experience on leading edge materials challenges facing the auto industry, Brewer said.

Dr. Brewer is an associate professor of metallurgical and materials engineering, and Dr. Barkey is a professor of aerospace engineering and mechanics.